Air Pollution in Steel Industry: Environmental, Health & Social Impact

The steel industry emits several pollutants including particulate matter and carbon dioxide. Image Courtesy: mactool.com

The steel manufacturing industry is one of the biggest industries in the world. Steel is primarily sourced from iron ore, and 98% of mined iron ore goes into manufacturing steel. This is a general story of how steel is made.

Steel is an essential commodity since it facilitates many other industries including construction, automobile, machinery, electrical equipment, and a variety of products ranging from cookware to furniture. It is estimated that by 2050, the demand for steel will grow by five times. The steel manufacturing process is energy-intensive and emits several pollutants including carbon dioxide and particulate matter (PM).

India is the second-largest steel producer in the world. In 2020, India overtook Japan to become the largest global producer of steel after China, with a net crude steel production of 99.6 metric tons.

Steel Making Process Steps:

The first step involves mining iron ore or as easy it can be described as the first step in the process of making steel from iron ore. This is a very polluting process that uses coal for blasting, etc. It releases several pollutants such as oxides of sulphur, PM, and fugitive dust.

Coke Oven

Coke oven emissions are a mixture of coal tar, VOCs, arsenic, beryllium, chromium, etc. These are toxic and may even be carcinogenic.

Blast Furnace

In the blast furnace, the iron ore is melted into liquid iron. This method is called the Basic Oxygen Method. A mixture of metallic ore, coke and fluxing agents such as limestone is fed into the furnace, and the result is pig iron or crude iron, which is later converted to steel.

An alternative step is the EAF (Electric Arc Furnace) method, which uses high temperatures to melt the scrap steel, instead of pig iron. Both processes produce pollutants such as hydrocarbons, carbon monoxide, PM, NO2 and SO2.

Primary Steel Making Process

This stage involves Primary Steel Making/Forming, in which hot rollers are used to make the steel bend into a desired shape. It also involves shaping, drilling, welding, coating with zinc, tempering with heat and surface treatment, etc. For this, the PM and oxides of sulphur and nitrogen are important pollutants of this process.

Notable Green Practices Followed by The Steel Industry

The steel industry has been instrumental in following sustainability practices like the ones mentioned below:

- Sustainable Light Steel Frame Construction - This type of construction with steel involves pre-engineered parts that are easy to set up and dismantle as well. Steel frame constructions require less extensive foundations and involve lesser time. They considerably reduce emissions at construction sites.

- Packaging with Steel - Steel contributes extensively to the circular economy since it can be endlessly recycled and remade without any loss to quality. Companies such as Unilever have started to take advantage of this benefit that steel brings, by using steel bottles and jars to package consumer goods such as shampoos.

- Using Slag to Sustain Marine Environment - Steel companies such as POSCO, Japan, have been using containers made of slag (a byproduct of steel) to fight the desertification of marine algae forests in the South Korean coast since 2007. Slag is a dense, rock-like material. Algae is planted in the slag containers; their density and weight protect algae forests from typhoons and tsunamis.

However, the primary step towards sustainability lies in acknowledging and addressing the pollution emitted in the production of steel. This not only safeguards the health of employees but also ensures surrounding areas are not impacted by pollution. This is irreplaceable and takes precedence over most other practices.

Where does Steel Industry Pollution Stand in India?

The steel industry is the third-largest contributor to air pollution.

The steel industry is the third-largest contributor to air pollution and one of the largest causes of industrial pollution in India with highest rates of carbon dioxide emissions. Steel particularly requires coal for energy, so a lot of emission is caused by coal combustion. Steel plants emit air pollutants such as particulate matter (PM2.5 and PM10), carbon dioxide, sulphur oxides, nitrogen oxides, carbon monoxide, etc.

Where Does the Steel Industry Stand in Pollution Control?

The environmental impact of steel production can be figured out through a study conducted by the Centre for Science and Environment, Delhi in 2012. The Organization studied the practices of the Indian steel industry for two years and prepared an environmental profile, giving it a rating of 19 out of 100. A 2012 article published in DownToEarth observed that the steel sector was struggling to meet the minimum statutory pollution norms.

This highlights the urgent need for pollution control to be taken up seriously by industries. Not having in place effective pollution control systems can cause serious damage to an industry’s brand image and reputation, apart from compromising the health of its workers and surrounding communities. There is also the business risk of suffering a plant shutdown for violation of guidelines.

- In 1994, the residents of an industrial town near Nagpur, Maharashtra, protested against one of the biggest steel manufacturers in India for polluting their local water bodies.1 This prompted the government to consider taking action against them. The town’s local body furthered their commitment to oppose pollution, almost 3 decades back.

- In 2020, villagers of Jagatsinghpur district in Odisha passed a resolution to not permit one of India’s leading steel manufacturers to set up a thermal power plant for its needs over a premises of 2900 acres in their surroundings. 2 This shows the public distrust that is a consequence of companies not taking steel industry pollution control methods seriously.

- In Zenica, Bosnia, citizens took to the street in 2012 to protest the damaging extent of air pollution caused by one of the world’s leading India-based steel manufacturers, who owned and operated a manufacturing plant in the town. The damage caused was so severe that most households in the town had at least one family member who had died from cancer, a direct consequence of pollution, according to a report in The Guardian in 2017. 3

In Zenica, Bosnia, citizens took to the street to protest the damaging extent of air pollution caused by a leading steel manufacturer. Image courtesy: balkaninsight.com

Evidently, steel industry pollution control goes a long way in ensuring a company’s health and success. These have not only contributed to a strain-free relationship with surrounding communities and a good brand image. It is an open secret that businesses that adopt sustainability as part of their core enjoy greater overall growth and success.

Existing Pollution Control Methods in Steel Industries and Their Efficacy

Conventionally, pollution control equipment in the steel manufacturing process includes point-source pollution control equipment such as electrostatic precipitators, baghouses, pulse jet filters and industrial scrubbers. However, these have a limited and clearly defined area of coverage, and therefore, cannot treat fugitive emissions and ambient air pollution very effectively. The above-mentioned methods are energy-consuming and require regular and expensive maintenance. They are not very effective in treating ambient air pollution either.

Challenges in Pollution Control - Fugitive Emissions

Fugitive emissions are unaccounted emissions that escape a point source. Image Courtesy: treehugger.com

One of the major challenges faced by the steel industry is unaccounted or ‘fugitive’ emissions. Fugitive dust meanings refer to pollutants that are ‘fugitive’ or escape from a source without being accounted for. Regular emissions from known sources are accounted for and hence easier to track and control. Fugitive emissions, on the other hand, are difficult to track since their source is unknown. Hence, they contribute to ambient air pollution in an untraceable way. The problem of fugitive emissions occurs during every stage of the steel manufacturing process, and poses a huge challenge.

What the Steel Industry can Benefit from - Pollution Control to Improve Occupational Health and Safety in Steel Manufacturers In India

Addressing the environmental impact of steel production and the problem of emissions is an important practice that a lot of steel industries are not currently following in an optimum manner. The Indian government aims to decrease emissions by one-third, by 2030. This comes at a time when the steel industry is set to increase its production output. The air pollution caused by the steel industry must be addressed immediately and in a big way, in order to comply with the norms of the government.

Practices such as carbon capture and sequestration (CCS) are one of the measures to control industrial pollution, which remove carbon dioxide at source from industrial plants, are both very expensive and require high energy, which in turn may be very polluting. Studies show that CCS can lead to a 25% increase in emissions from burning coal, etc. 4 The only solution is an affordable one that can cover large areas efficiently and is cost effective.

An ideal solution to industrial pollution in steel industries should i) tackle the problem efficiently, ii) address fugitive emissions, iii) be cost-effective and sustainable.

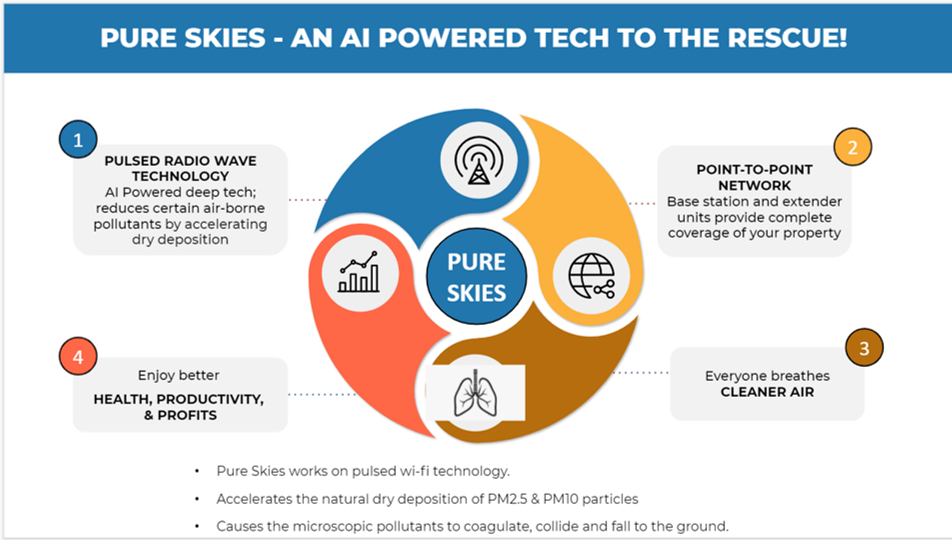

Devic Earth’s Pure Skies is a breakthrough technology that does exactly this. It addresses large areas, cleaning ambient air pollution including fugitive and regular emissions. Pure Skies reduces air pollution by removing pollutants such as PM2.5, PM10, NOx, SOx and others from the air.

Pure Skies is based on pulsed Wi-Fi technology. This is a filter-less and intelligent system that spreads signals over an area and clears pollutants. The technology accelerates the natural clearance of air pollutants and their formation into dry deposition. It operates in the normal Wi-Fi signal range and is completely safe. Further, it does not interfere with the activities of a manufacturing plant in any way.

Case Study

Pure Skies was installed at one of India’s leading steel manufacturing plants to mitigate the problem of high, often unaccounted emissions. Despite having in place pollution control systems, the plant still faced high emission of pollutants, and associated risks such as opposition from neighbouring communities, and also the administrative roadblocks in terms of closing the plant and/or being charged heavy fines.

Within four months of installation, Pure Skies

- Reduced PM2.5 levels by 83%

- Reduced PM10 levels by 76%

The plant benefitted from the immense drop in pollution levels, and enjoyed the security and enhanced performance enabled by Pure Skies.

Economic Benefits

An underrated benefit of clean air is improved productivity from the workforce. A study conducted by one of our clients in their office space demonstrated that after they installed our air cleaners, sick leave was reduced by up to 13%. If this is the result of better air quality at an office space, imagine how much more the workforce’s productivity will be, in an industrial plant.

Benefits of Pure Skies

- It covers large areas. One unit of Pure Skies can easily cover acres of a premise.

- It is affordable. Pure Skies is a subscription service and lets you avail clean air at an affordable monthly rate, also providing the flexibility to cancel anytime.

- It has a high rate of efficacy. Pure Skies has a proven high efficacy rate, and increases the air quality by bringing down the steel industry pollution by 33-90%.

- It is filter-less. Pure Skies avoids all the hassles and extra expenses that most other air cleaners demand. It is a silent, plug and play technology.

- It leads to improved productivity and profitability. Installing Pure Skies has restored a great deal of productivity by reducing sick leaves and increasing employee productivity. Customers who've installed Pure Skies have seen a 13% year-on-year reduction in their employees' sick leave.

- Monitor air quality in real-time. Pure Skies comes with a third party air quality monitor. It lets you visualise your air quality baseline, and then clearly note the reduction in levels of pollutants.

The World’s First Clean Air Subscription

Pure Skies is available for subscription, like most of today’s smart and user-friendly services. With a one-time activation fee, enjoy clean air always, with the flexibility to opt out anytime. Avoid CapEx investment; pay a monthly fee as you go.

Subscribe to Pure Skies and enjoy exclusive benefits!

Our subscription plan comes with great advantages like flexibility, low cost and convenience.

With Pure Skies, boost your performance, improve plant hygiene and achieve your sustainability goals.

GET PURE SKIES FOR YOUR STEEL PLANT TODAY!

(This article is conceptualized and co-written by Shashank Aggarwal & Vidhya Sreenivasan)

References

- https://www.downtoearth.org.in/news/steel-manufacturer-in-the-dock-29292

- https://www.downtoearth.org.in/news/environment/palli-sabha-at-odisha-s-dhinkia-opposes-steel-cement-power-plant-69508

- https://www.theguardian.com/cities/2017/feb/14/arcelor-mittal-failing-emissions-air-pollution-zenica-bosnia

- https://www.univie.ac.at/photovoltaik/vorlesung/ss2014/unit2/Energy_policy2010.pdf

.svg)

Post Comments