Air pollution control equipment for steel plants

What we did:

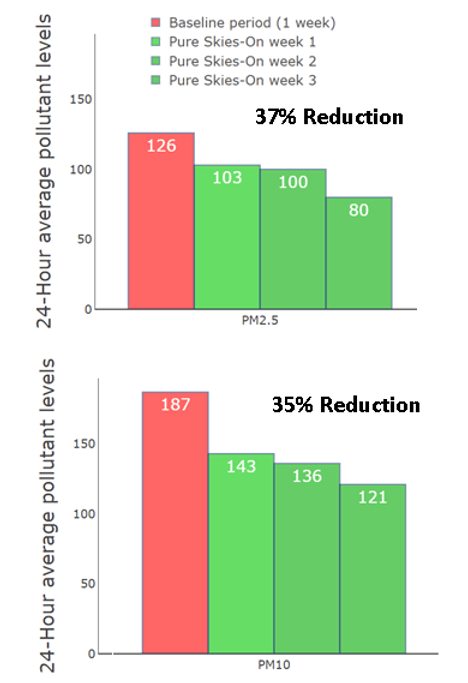

Pure Skies pollution control equipment reduced PM2.5 and PM10 about 37% and 35%, respectively, at a steel plant.

The problem:

Anyone working in a factory where steel is being processed is done knows that it can be dirty. Welding shot blasting, cutting, and other metal working operations generate fumes containing manganese, lead, hexavalent chromium, and other toxic compounds.

PC:img.caixin.com

Steel plants generate significant amounts of pollution that affect workers’ well being.

One of Devic Earth’s partners, a leading supplier of Ready to Assemble Steel Systems, wanted to improve air quality inside one of their plants. Prior to coming to us, they had already trialed several industrial air cleaners, each with disappointing results.

Air quality measured inside the plant before installing inside was poor. Particulate matter – PM2.5 and PM10 – were 126 and 187 μg/m3, respectively, averaged over one week. This is much higher than what is recommended by the National Ambient Air Quality Standards (PM2.5 < 60 μg/m3 & PM10 < 100 μg/m3) and 5 to 10 times higher than standards of the World Health Organization..

Employees were exposed to high levels of harmful pollutants which would impact their health and productivity.

Apart from a few ventilation fans, there were no fume extraction units or facility-wide air pollution control equipment installed.

The solution:

One Pure Skies 6000 system was installed inside the factory. The installation consisted of one Pure Skies base station, two extenders, and two third party air quality monitors (Airveda Pvt. Ltd., Delhi).

The system was configured to handle particulate pollutants (PM10 and PM2.5) across the entire indoor area of the plant – approximately 60,000 sq. ft.

Indoor air pollutant levels were monitored continuously at appropriate locations inside the plant to help the customer understand the efficacy of Pure Skies, as well as to provide real-time data.

It took just one afternoon to complete the installation. The base station, two extenders, and both air quality monitors were installed on support beams. No floor space was required. Equipment was plugged in and connected wirelessly to the local GSM data network in the area.

Power requirements: Routine power supply (ordinary 10A sockets). Each base station and air quality monitor comes with battery backup.

Once online, Devic Earth monitors the performance of each air pollution control unit 24x7.

The plant manager and EHS head were given secure logins to view their property’s air quality data on a convenient app.

The outcome:

After Pure Skies was powered On, a steady improvement was observed in the air quality.

In just three weeks, Pure Skies reduced levels of PM2.5 and PM10 were reduced by 37% & 35%, respectively (Figure 1). Plant output, number of workers, and local weather patterns remained stable during this period.

Figure 1: Average pollutant levels and % reduction at the steel plant. The red and green bars are the Pure Skies-Off (7-days) and Pure Skies-On periods (7-days), respectively. The successive green bars depict the incremental decrease in the levels of the pollutants over 7-day intervals. Data source: 3rd party air quality monitor (Airveda Pvt. Ltd., Gurgaon), pre-calibrated against a reference grade monitor.

Pure Skies is a state-of-the-art technology that ensured that the employees working in the plant breathed clean air at work.