Air pollution control equipment for Manufacturing plants

What we did:

Pure Skies pollution control equipment reduced PM2.5 and PM10 about 80% and 90%, respectively, at a heavy manufacturing plant.

The problem:

One of Devic Earth’s customers is an MNC which manufactures earth moving equipment. The customer was particularly concerned about the health effects of air quality inside one of their plants in the Delhi-NCR area, covering approximately 18,000 sq.

Levels of air pollutants inside the plant were at hazardous levels before Pure Skies was installed.

Baseline air quality was measured over a one-week period before a Pure Skies air purifier was installed. Levels of particulate pollutants – PM2.5 & PM10 – inside the plant werehazardous:441 ± 21 µg/m3&494 ± 24 µg/m3,respectively. These exceed both National Ambient Air Quality Standards, and are about 20 times higher than the standards of the World Health Organization.

Processes such as welding, metal cutting, and metal buffing lead to high levels of particulate pollution inside the plant.

Other sources of pollution include neighboring factories in the industrial zone in which they are located, as well as vehicle emissions from the adjacent highway.

Portable fume extractors and an extensive network of exhaust fans and ducting were in place, but there was minimal benefit.

The solution:

One Pure Skies 6000 and one third-party air quality monitor from Airveda (Airveda Pvt. Ltd., Gurgaon) were installed.

Figure 1: Pure Skies base station installed on a pedestal inside the plant floor. An air quality monitor was installed about 50 m away from the base station. An additional Pure Skies extender unit (not shown) was placed just outside the main shutters to the plant.

Installation took a few hours. Equipment was installed on support columns or beams. No floor space was required.

Due to high ambient pollution levels in Delhi-NCR, and especially in the industrial zone, air pollution levels outside the plant were also exceedingly high. Ambient PM levels recorded by the CPCB reference air quality station just a few km away would frequently cross 300 mcg/m3 during the smog season. That’s like breathing a dozen cigarettes at once!

To compensate for high air pollution levels outside the plant, Devic Earth technicians installed an additional Pure Skies extender unit just outside the plant shutters to minimize the entry of polluted air into the plant premises.

Power requirements: Routine power supply (ordinary 10A sockets). Each base station and air quality monitor comes with a battery backup.

Once online, the performance of each air pollution control unit is monitored by Devic Earth 24x7.

The outcome:

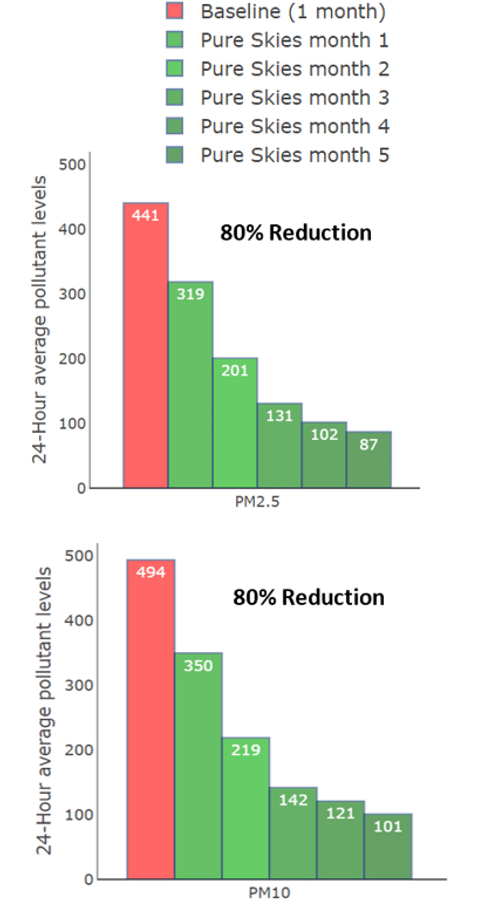

Within 4-weeks of installing the Pure Skies unit in the plant, the 24-hour average PM2.5 and PM10 levels were reduced by 28% and 29%, respectively. Over the next 5 months, levels of particulate pollutants – PM10 and PM2.5 – were reduced by 80-90% with Pure Skies, as compared to baseline!

Plant output and employee's head count were steady during this period. These benefits in air quality have been sustained over the past year.

Figure 2: Average pollutant levels and % reduction at the earth-moving equipment manufacturing plant. The red and green bars are the Pure Skies-Off(1 month) and Pure Skies-On periods (1 month), respectively. The successive green bars depict the incremental decrease in the levels of the pollutants over 1-month intervals. Data source: 3rd party air quality monitor (Airveda Pvt. Ltd., Gurgaon), pre-calibrated against a reference grade monitor.

Unlike air purifiers which use HEPA filters or ESPs, Pure Skies air purifiers use pulsed radio technology in the Wi-Fi spectrum to cover large areas effectively and maintain low levels of particulate pollutants over time. This makes Pure Skies an excellent choice for improving air quality over large indoor spaces.