Pure Skies for Cement Industries - Mitigating Ambient Air Pollution

At Devic Earth, we have delivered 18 million+ square meter area of clean air across Industries.

With the largest area of coverage, lowest costs, and highest efficacy, improve your air quality by a minimum of 33% with Pure Skies.

.png)

Enquire Now!

Fill in your details here and

get your Subscription plan today.

Case Study: Pure Skies For Cement Plants

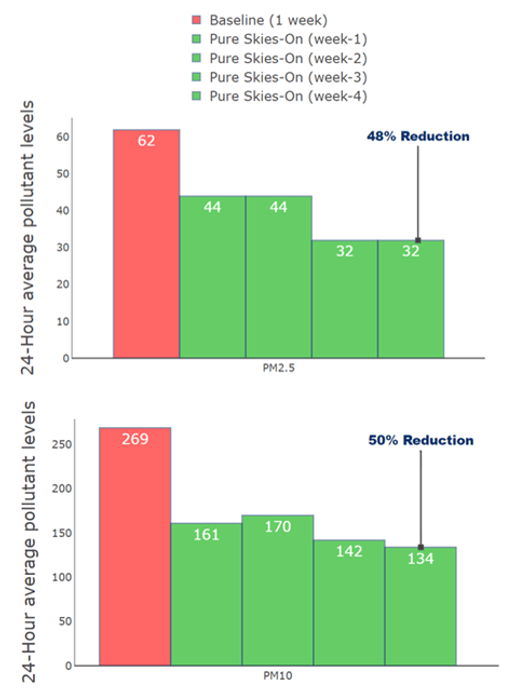

Pure Skies air pollution control equipment reduced PM2.5 and PM10 and 50% and 48%, respectively, at one of the leading manufacturers in the cement industry.

The Problem:

Anyone working in a factory where cement is being produced knows how poor air quality can get. Particulate pollutants – PM10 and PM2.5 – released during operations affect the well-being of workers at the plant, the plant’s residential colony, as well as surrounding communities.

PC: rechargenews.com

One of Devic Earth’s partners, a leading manufacturer in the cement industry, wanted to improve air quality at one of their plants. The plant was already equipped with the latest air pollution control equipment and followed best practices for the management of fugitive emissions.

Despite these measures, air quality measured within the plant premises was poor. Particulate matter –PM10 – was 269 μg/m3, averaged over one week. This is much higher than what is recommended by the National Ambient Air Quality Standards (PM10 < 100 μg/m3) and 5 to 10 times higher than standards of the World Health Organization

Employees were exposed to high levels of harmful pollutants which would impact their health and productivity.

The Solution:

One Pure Skies 9000 system (an earlier version of the current Pure Skies 24K model) was installed inside the factory. The installation consisted of 1 Pure Skies base station and 1 third party air quality monitors (of Airveda Pvt. Ltd., Delhi).

PC: www.constructionweekonline.in

The system was configured to handle particulate pollutants (PM10 and PM2.5) across the entire campus of the plant – approximately 100 acres.

Outdoor air pollutant levels were monitored continuously at appropriate locations inside the plant to help the customer understand the efficacy of Pure Skies, as well as to provide real-time data.

The plant manager and EHS head were given secure logins to view their property’s air quality data on a convenient app to monitor the functioning closely.

Technical Details - Installation

Power requirements: Routine power supply (ordinary 10A sockets). Each base station and air quality monitor comes with a battery backup.

Once online, the performance of each air pollution control unit is monitored by Devic Earth 24x7.

The Outcome:

After Pure Skies was powered On, a steady improvement was observed in the air quality (Figure 1).In just four weeks, Pure Skies reduced levels of PM2.5 and PM10 by 48% and 50%, respectively.

Plant output, number of workers, and local weather patterns remained stable during this period.

Figure 1: Change in pollution levels with Pure Skies at a cement plant. The red and green bars are the Pure Skies-Off (7 days) and Pure Skies-On periods (7 days), respectively. The successive green bars depict the incremental decrease in the levels of the pollutants over 7-day intervals. Data source: 3rd party air quality monitor (Airveda Pvt. Ltd., Gurgaon), pre-calibrated against a reference grade monitor.

Pure Skies is a state-of-the-art technology that ensured that the employees at the plant, the plant’s residential colony, and surrounding communities breathe clean air.

What Our Client's Say

P Sreenivasa Raju

Sr. Gen Manager, ACC Cement"After deploying Devic Earth's Pure Skies technology at our cement plant, PM2.5 reduced by 48% and PM10 by 50% in 4 weeks. These results are magical.

We plan to install this system across our manufacturing plants in due course of time".

Anand Desai

MD, Anupam Rasayan"Pure Skies is an impressive product that reduced pollutant levels by 66% at our manufacturing plant. We were glad to have a vast area of clean air at our premises. Pure Skies, with its unique technology, was able to give us a very effective solution to air pollution. In addition to giving back to the community while improving customer experience, it also assist us to boost employee productivity".

.jpg?width=120&height=120&length=120&name=Dilip%20(1).jpg)

Dilip Jayaram

CEO, PROCAM International''We deployed the Pure Skies System at the IAAF GOLD label Airtel Delhi Half Marathon’ 2018 and the results achieved were miraculous. Buoyed by the success and armed with the learnings from the ADHM, Devic Earth also deployed the systems at the Tata Steel Kolkata 25K and were able to achieve better results. The results have ranged between 30 - 54% improvements''

.jpg?width=120&height=120&length=120&name=ASHISH%20SIR%20(1).jpg)

Ashish Khandelwal

Executive Director, BL Agro Industries“We have also installed state-of-the-art air purifiers across our units that help curb and map our emissions, giving us a chance to minimize the emissions. This had led to improve the air quality of the industrial area by 88% making the environment safe and breathable."

Haresh Mirpuri

CEO and Creative Director''Installing Devic Earth’s solution for improved air quality – Pure Skies system, proved to be a vital one. It is simple yet very effective! Secured real-time data access was given to check the air quality levels after the system was turned on. Increase in air quality was duly noticed and even felt by our working staff in the manufacturing unit. Air quality increased by more than 50% during the 16 days while pure skies was on. I am convinced that it’s a great product to keep our air quality safe and healthy for us''