Air pollution control equipment for Chemical Industries

What we did:

Pure Skies pollution control equipment reduced PM2.5 and PM10 about 53% and 49%, respectively, at a chemical industry.

The problem:

The chemical industry includes producers of commodity chemicals such as organic and inorganic chemicals and industrial gases, and specialty chemicals such as pharmaceutical products and essential oils. While these plants produce essential items that we all use daily, they also create air pollution that can be problematic both for the plant’s employees as well as neighboring communities.

PC: www.azocleantech.com

One of Devic Earth’s partners, chemical industry, wanted to improve ambient air quality at one of their plants. The plant was already equipped with the latest air pollution control equipment and followed best practices for management of fugitive emissions.

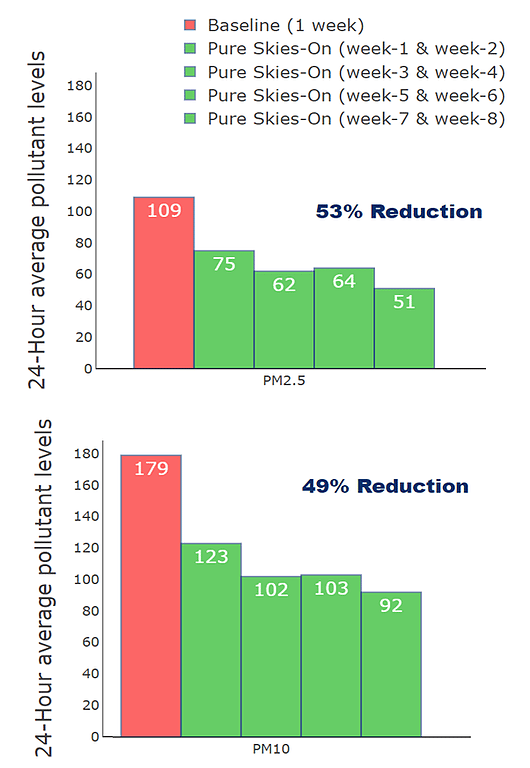

Despite these measures, air quality measured inside the plant inside was poor. Particulate matter – PM2.5 and PM10 – were 109 and 179 μg/m3, respectively, averaged over one week. This is much higher than what is recommended by the National Ambient Air Quality Standards (PM2.5 < 60 μg/m3 & PM10 < 100 μg/m3) and 5 to 10 times higher than standards of the World Health Organization..

Employees and visitors were exposed to high levels of harmful pollutants which would impact their health and productivity.

The solution:

One Pure Skies 3000 systems were installed inside the Plant. The installation consisted of one Pure Skies base station and one third party air quality monitors (Airveda Pvt. Ltd., Delhi).

The system was configured to handle particulate pollutants (PM10 and PM2.5) across the entire campus of the plant – roughly 50 acres.

Outdoor air pollutant levels were monitored continuously at appropriate locations inside the campus to help the customer understand the efficacy of Pure Skies, as well as to provide real-time data.

For comparison, a reference monitor run by the state pollution control board located about 3.5 km away was used as the comparison monitor, outside the Pure Skies zone of influence.

It took just one afternoon to complete the installation. The base station and air quality monitor were installed on either building rooftops or utility poles. No floor space was required. Equipment was plugged in and connected wirelessly to the local GSM data network in the area.

Power requirements: Routine power supply (ordinary 10A sockets). Each base station and air quality monitor comes with battery backup.

Once online, the performance of each air pollution control unit is monitored by Devic Earth 24x7.

The plant manager and EHS head were given secure logins to view their property’s air quality data on a convenient app.

The outcome:

After Pure Skies was powered On, a steady improvement was observed in the air quality (Figure 1).

In just six weeks, Pure Skies reduced levels of PM2.5 and PM10 were reduced by 53% and 49%, respectively.

Plant output, number of workers, and local weather patterns remained stable during this period.

Figure 1: Improvements in air pollution levels with Pure Skies at a Chemical Industry. The red and green bars are the Pure Skies-Off (7-days) and Pure Skies-On periods (14-days), respectively. The successive green bars depict the incremental decrease in the levels of the pollutants over 14-day intervals. Data source: 3rd party air quality monitor (Airveda Pvt. Ltd.), pre-calibrated against a reference grade monitor.

Pure Skies is a state-of-the-art technology that ensured that the employees working in the plant breathed clean air at work.